Shreeyan Connect is a reputed manufacturer and supplier of high-quality threaded, lap joint, and socket weld flanges that cater to a wide range of industrial applications. With precision engineering and strict compliance to international standards such as ANSI, ASME, and DIN, our flanges are built to deliver superior performance, strength, and reliability even under the most challenging operating conditions.

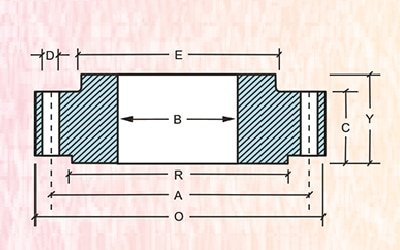

THREADED

Suitable for piping systems with small diameters or in hazardous regions where welding is not practical, these flanges are simple to install without welding and are ideal for low-pressure systems.

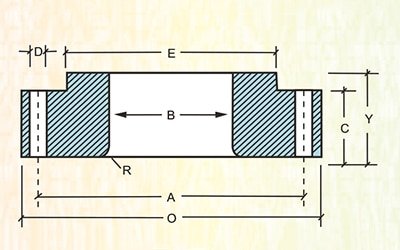

LAP JOINT

These flanges are ideal for sectors like chemical processing and food production since they are made for applications that need frequent disassembly. They are paired with stub ends and have a high degree of alignment flexibility.

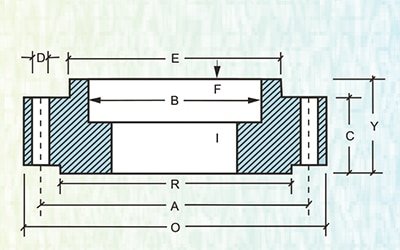

SOCKET WELD

These flanges are frequently found in high-pressure pipes and are built to offer a robust, leak-proof connection, guaranteeing longevity and effective fluid or gas movement.

| CLASS 600 | ||||||||||||||||

| Nominal Pipe Size | Outside Diameter of Flange O | Dia of Bolt Circle A | Dia of Bolt Holes D | No. of Holes | Thickness of Flange C | Hub | Length Through Hub | Bore | Diameter of R/F R | Depth of Socket F | ||||||

| Diameter of Hub E | Hub of W/N X | S/O & S/W Y | W/N Y | L/J Y | S/O & S/W B | L/J B | SCH STD W/N B | |||||||||

| 15 | 95.2 | 66.7 | 15.9 | 4 | 14.3 | 38.1 | 21.33 | 22.2 | 52.4 | 22.3 | 22.3 | 22.8 | 15.70 | 34.9 | 9.5 | |

| 20 | 117.5 | 82.5 | 19.0 | 4 | 15.9 | 47.6 | 26.67 | 25.4 | 57.1 | 25.4 | 27.7 | 28.1 | 20.80 | 42.9 | 11.1 | |

| 25 | 123.8 | 88.9 | 19.0 | 4 | 17.5 | 54.0 | 33.40 | 27.0 | 61.9 | 26.9 | 34.5 | 35.0 | 26.60 | 50.8 | 12.7 | |

| 32 | 133.3 | 98.4 | 19.0 | 4 | 20.6 | 63.5 | 42.16 | 28.6 | 66.7 | 28.4 | 43.2 | 43.6 | 35.00 | 63.5 | 14.2 | |

| 40 | 155.6 | 114.3 | 22.2 | 4 | 22.2 | 69.8 | 48.26 | 31.7 | 69.8 | 31.7 | 49.5 | 50.0 | 40.80 | 73.0 | 15.8 | |

| 50 | 165.1 | 127.0 | 19.0 | 8 | 25.4 | 84.1 | 60.31 | 36.5 | 73.0 | 36.5 | 62.0 | 62.4 | 53.30 | 92.1 | 17.4 | |

| 65 | 190.5 | 149.2 | 22.2 | 8 | 28.6 | 100.0 | 73.02 | 41.3 | 79.4 | 41.1 | 74.7 | 75.4 | 62.40 | 104.8 | 19.0 | |

| 80 | 209.5 | 168.3 | 22.2 | 8 | 31.8 | 117.5 | 88.90 | 46.0 | 82.5 | 45.9 | 90.7 | 91.4 | 77.90 | 127.0 | – | |

| 100 | 273.0 | 215.9 | 25.4 | 8 | 38.1 | 152.4 | 114.30 | 54.0 | 101.6 | 53.8 | 116.1 | 116.8 | 102.20 | 157.2 | – | |

| 125 | 330.2 | 266.7 | 28.6 | 8 | 44.4 | 188.9 | 141.30 | 60.3 | 114.3 | 60.4 | 143.8 | 141.5 | 128.10 | 185.7 | – | |

| 150 | 355.6 | 292.1 | 28.6 | 12 | 47.6 | 222.2 | 168.27 | 66.7 | 117.5 | 66.5 | 170.7 | 171.4 | 154.00 | 215.9 | – | |

| 200 | 419.1 | 349.2 | 31.7 | 12 | 55.6 | 273.0 | 219.07 | 76.2 | 133.3 | 76.2 | 221.5 | 222.2 | 202.70 | 269.9 | – | |

| 250 | 508.0 | 431.8 | 34.9 | 16 | 63.5 | 342.9 | 273.05 | 85.7 | 152.4 | 111.2 | 276.3 | 277.3 | 254.50 | 323.8 | – | |

| 300 | 558.8 | 488.9 | 34.9 | 20 | 66.7 | 400.0 | 323.85 | 92.1 | 155.6 | 117.3 | 327.1 | 328.1 | 304.80 | 381.0 | – | |

| 350 | 603.2 | 527.0 | 38.1 | 20 | 69.9 | 431.8 | 355.60 | 93.7 | 165.1 | 127.0 | 359.1 | 360.1 | 336.50 | 412.7 | – | |

| 400 | 685.8 | 603.2 | 41.3 | 20 | 76.2 | 495.3 | 406.40 | 106.4 | 177.8 | 139.7 | 410.5 | 411.2 | 387.30 | 469.9 | – | |

| 450 | 742.9 | 654.0 | 44.4 | 20 | 82.6 | 546.1 | 457.20 | 117.5 | 184.1 | 152.4 | 461.8 | 462.2 | 438.10 | 533.4 | – | |

| 500 | 812.8 | 723.9 | 44.4 | 24 | 88.9 | 609.6 | 508.00 | 127.0 | 190.5 | 165.1 | 513.1 | 514.3 | 488.90 | 584.2 | – | |

| 600 | 939.8 | 838.2 | 50.8 | 24 | 101.6 | 717.5 | 609.60 | 139.7 | 203.2 | 184.1 | 615.9 | 615.9 | 590.50 | 692.1 | – | |

| CLASS 900 | ||||||||||||||||

| Nominal Pipe Size | Outside Diameter of Flange O | Dia of Bolt Circle A | Dia of Bolt Holes D | No. of Holes | Thickness of Flange C | Hub | Length Through Hub | Bore | Diameter of R/F R | Depth of Socket F | ||||||

| Diameter of Hub E | Hub of W/N X | S/O & S/W Y | W/N Y | L/J Y | S/O & S/W B | L/J B | SCH STD W/N B | |||||||||

| 15 | 120.6 | 82.5 | 22.2 | 4 | 22.2 | 38.1 | 21.33 | 31.7 | 60.3 | 31.7 | 22.3 | 22.8 | 15.70 | 34.9 | 9.5 | |

| 20 | 130.2 | 88.9 | 22.2 | 4 | 25.4 | 44.4 | 26.67 | 34.9 | 69.8 | 35.0 | 27.7 | 28.1 | 20.80 | 42.9 | 11.1 | |

| 25 | 149.2 | 101.6 | 25.4 | 4 | 28.6 | 52.4 | 33.40 | 41.3 | 73.0 | 41.1 | 34.5 | 35.0 | 26.60 | 50.8 | 12.7 | |

| 32 | 158.7 | 111.1 | 25.4 | 4 | 28.6 | 63.5 | 42.16 | 41.3 | 73.0 | 41.1 | 43.2 | 43.6 | 35.00 | 63.5 | 14.2 | |

| 40 | 177.8 | 123.8 | 28.6 | 4 | 31.8 | 69.8 | 48.26 | 44.4 | 82.5 | 44.4 | 49.5 | 50.0 | 40.80 | 73.0 | 15.8 | |

| 50 | 215.9 | 165.1 | 25.4 | 8 | 38.1 | 104.8 | 60.31 | 57.1 | 101.6 | 57.1 | 62.0 | 62.4 | 53.30 | 92.1 | 17.4 | |

| 65 | 244.5 | 190.5 | 28.6 | 8 | 41.3 | 123.8 | 73.02 | 63.5 | 104.8 | 63.5 | 74.7 | 75.4 | 62.40 | 104.8 | 19.0 | |

| 80 | 241.3 | 190.5 | 25.4 | 8 | 38.1 | 127.0 | 88.90 | 53.9 | 101.6 | 53.8 | 90.7 | 91.4 | 77.90 | 127.0 | – | |

| 100 | 292.1 | 234.9 | 31.7 | 8 | 44.4 | 158.7 | 114.30 | 69.8 | 114.3 | 69.8 | 116.0 | 116.8 | 102.20 | 157.1 | – | |

| 125 | 349.2 | 279.4 | 35.0 | 8 | 50.8 | 190.5 | 141.30 | 79.3 | 127.0 | 79.2 | 143.7 | 144.5 | 128.10 | 185.7 | – | |

| 150 | 381.0 | 317.5 | 31.7 | 12 | 55.6 | 234.9 | 168.27 | 85.8 | 139.7 | 85.8 | 170.6 | 171.4 | 154.00 | 215.9 | – | |

| 200 | 469.9 | 393.7 | 38.1 | 12 | 63.5 | 298.4 | 219.07 | 101.6 | 162.0 | 144.3 | 221.4 | 222.2 | 202.70 | 269.8 | – | |

| 250 | 546.1 | 469.9 | 38.1 | 16 | 69.8 | 368.3 | 273.05 | 107.9 | 184.1 | 127.0 | 276.3 | 277.3 | 254.50 | 323.8 | – | |

| 300 | 609.6 | 533.4 | 38.1 | 20 | 79.3 | 419.1 | 323.85 | 117.4 | 200.0 | 142.7 | 327.1 | 328.1 | 304.80 | 381.0 | – | |

- All Dimensions are in Millimeters.

- Flanges except Lap Joint will be furnished with (1.6) Raised Face, which is included in 'Thickness (C)' and 'Length through Hub (Y)'

To meet the needs of industries such as oil & gas, petrochemicals, power generation, and water treatment, Shreeyan Connect offers flanges in a wide range of sizes, materials, and pressure ratings. With a strong commitment to quality and customer satisfaction, we have become a trusted choice in the global market. Our focus on precision engineering, timely delivery, and competitive pricing makes us a preferred partner for businesses worldwide.